TCL #33: The Material Revolution

From six-month molecular discoveries to $1.50 hydrogen, technology is compressing the innovation timeline.

The marriage of silicon and science is yielding unexpected offspring. From Finnish laboratories where algorithms hunt for molecules that can banish "forever chemicals" from water, to Swiss waste plants preparing to trap 120,000 tonnes of carbon dioxide annually, a quiet revolution is unfolding in materials science. What once took a decade of trial and error can now be compressed into six months of computational wizardry.

Oak Ridge National Laboratory has built databases for thousands of 3D-printing materials, while Nestlé and IBM teach machines to decode packaging secrets. In Milan, a startup promises hydrogen at $1.50 per kilogram, competitive enough to challenge fossil fuels, yet clean enough to satisfy climate concerns. The common thread is a new model of partnership between public research, corporations, and startups that offers a glimpse of how the materials underpinning modern life might be reimagined.

To receive these updates in your inbox, subscribe below. The future rarely announces itself, but patterns do.

Materials

- Oak Ridge National Laboratory (ORNL) and JuggerBot 3D are collaborating to advance 3D printing capabilities, including the use of pellet-fed systems and dual materials. ORNL's open source Slicer 2 software was instrumental in enabling JuggerBot 3D's vision for pellet-fed 3D printing. The team developed a laser-based bead characterization system to improve printing accuracy by calibrating extruder speed and material output in real time. With ORNL's assistance, JuggerBot created a material database within their printers, containing process parameters for thousands of materials. The collaboration resulted in an automated, data-driven process that simplifies 3D printing operations, reducing the need for specialized knowledge. The collaboration is part of the Manufacturing Demonstration Facility (MDF) consortium, which aims to transform U.S. manufacturing.

- Kemira, a Finnish company that provides sustainable chemical solutions for water-intensive industries, has partnered with CuspAI, an AI company in materials science, to enhance materials innovation in the chemical sector. The partnership aims to accelerate the discovery and optimization of new materials, reducing the typical decade-long process to as little as six months using AI. The initial focus of the collaboration is on in silico development, with the first project targeting the removal of PFAS (forever chemicals) from water.

Water from Air

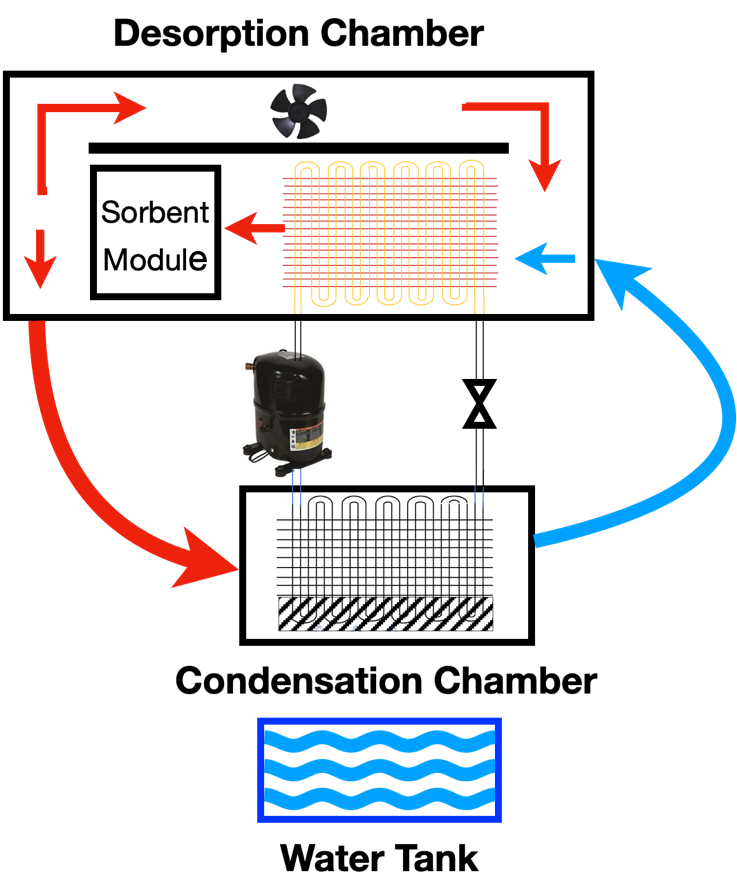

WaHa (Water Harvesting Inc.) has secured $8 million in Series A-1 funding. Founded in 2018 to commercialize desiccant materials and technologies, WaHa focuses on atmospheric water generation and humidity management. The company's technology has been successfully deployed in various locations, including the UAE, West Texas, and Stockholm.

Carbon Capture

KEZO and Sulzer have launched a pilot project for CO2 capture at a waste recycling plant in Hinwil, Switzerland. The project aims to validate the integration of carbon capture technology at KEZO's waste-to-energy plant in preparation for a new municipal solid waste incineration (MSWI) plant planned for 2030. Sulzer will provide a pre-assembled modular unit to capture up to 1000 tonnes of CO2 annually from the flue gas. The captured carbon will be utilized by a nearby greenhouse, demonstrating circular resource use. Successful validation could lead to a scaled carbon capture unit at the new MSWI facility, capturing up to 120,000 tonnes of CO2 annually.

Aviation Fuel

Natural State Renewables has partnered with Axens to advance the production of sustainable aviation fuel (SAF) from surplus forest biomass. The BioTfueL technology, developed by six major players in decarbonization, namely Avril, Axens, CEA, IFP Energies nouvelles (IFPEN), TotalEnergies, and thyssenkrupp Uhde, will be used to produce SAF with negative greenhouse gas (GHG) emissions. Natural State Renewables aims to utilize a combination of feedstock, process configuration, power generation, and CO2 emissions capture to achieve negative GHG emissions.

Battery

Nobian has partnered with Veolia to promote lithium production for batteries. Nobian developed a patented process that converts lithium chloride into lithium hydroxide monohydrate (LHM), a key raw material for batteries. Veolia has validated Nobian's process using its HPD crystallization technology, a range of fully integrated evaporation and crystallization processes used for producing premium chemical products, confirming its efficiency and applicability. The collaboration aims to scale up lithium production, enhancing Europe's strategic independence in lithium supply.

Packaging

Nestle and IBM Research are collaborating to develop AI and deep tech tools for packaging solutions. Using IBM's regression transformer, a generative AI tool has been created to understand the correlation between molecular features and physical-chemical properties, thus identifying novel high-barrier packaging materials. Nestle plans to use this technology to discover future packaging materials while considering cost, recyclability, and functionality.

Hydrogen Production

Tulum Energy, a methane pyrolysis startup based in Milan, has secured $27 million in venture financing to scale its turquoise hydrogen technology. The funding was led by CDP Venture Capital and TDK Ventures, with participation from several other investors. Tulum's technology produces clean hydrogen and solid carbon from natural gas or biogas without CO2 emissions. The funding will support the construction of a pilot plant in Pesqueria, Mexico, within Ternium's industrial complex. Ternium will serve as a partner for initial operations and potential hydrogen use in direct reduced iron (DRI) production. Tulum aims to produce hydrogen at a competitive price of $1.50 per kilogram which is 50 cents more than hydrogen derived from natural gas. The price does not yet account for the sale of carbon generated in the process.